Unlocking the Potential of Arduino in Industrial Automation and Control Systems

Exploring Arduino’s Role in Industrial Automation

Arduino, a versatile platform known for its role in prototyping and embedded systems, has garnered attention for its potential in industrial automation and control systems. While not a direct replacement for Programmable Logic Controllers (PLCs), Arduinos bring distinct advantages such as low cost and rapid design and implementation in specific applications.

Arduino’s Limitations in Industrial Automation

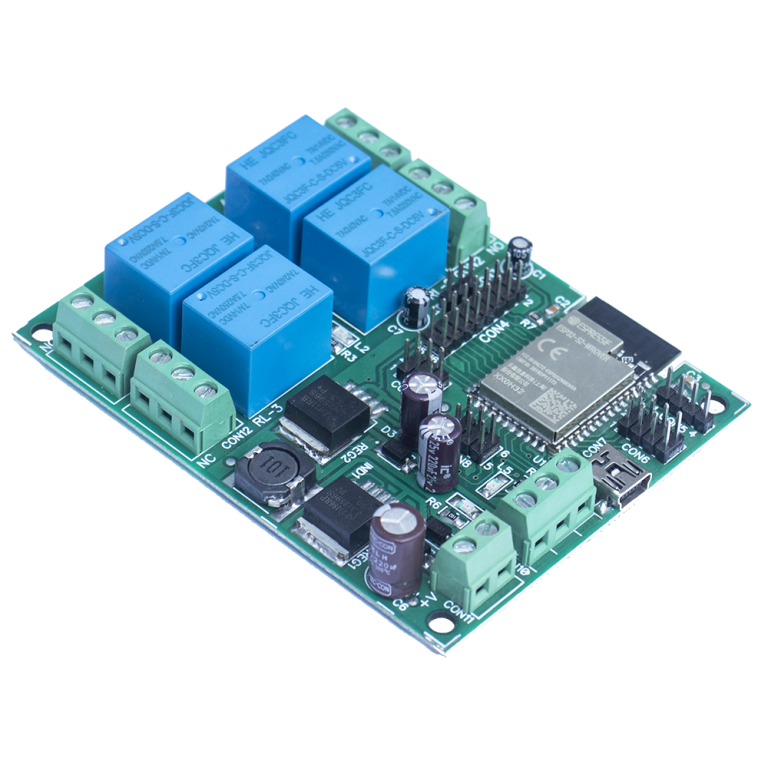

However, it’s crucial to acknowledge that Arduinos may fall short in meeting the performance, capacity, and robustness requirements of many automated industrial processes. Despite this, there are instances where Arduino-based solutions shine, like the Opta PLC range designed for professional use. With up to 58 inputs and outputs, digital, analog, and relay standard protocols, and connectivity options like Ethernet, Modbus, and WiFi, these applications showcase the adaptability of Arduino technology.

Arduino in Manufacturing: Prototyping and Beyond

In the manufacturing sector, Arduino finds a niche in the early stages of product development. It facilitates the prototyping of electronic hardware products and allows for the creation of custom PCBs for potential mass production. However, practical considerations, including cost, size, and power consumption limitations, may render Arduino less feasible for large-scale manufacturing.

The Professional Consideration

Arduino, often synonymous with hobby projects, can also find a place in professional finished devices. Its ability to run the same code on both inexpensive and professional hardware makes it a versatile choice. Yet, caution is warranted for long-term projects running continuously, as Arduino’s primary design focus lies in development and early prototyping, not sustained industrial use.

Bridging the Gap with “Ruggedized” Versions

Acknowledging the debates around Arduino’s suitability for industrial use, there are “ruggedized” industrial versions available. These variants address the specific demands of industrial applications, providing a potential bridge between Arduino’s versatility and the stringent requirements of professional settings.

Arduino in Professional Projects: Navigating Considerations

In professional projects, Arduino’s use is not without considerations and limitations. While optimized for commercial use, Arduino boards shine in prototyping and early-stage development. However, deploying Arduino in mass production demands careful evaluation of factors like power consumption, PCB size, and overall cost.

Striking a Balance

Despite its limitations, Arduino’s adaptability is showcased in professional settings. The availability of “ruggedized” industrial versions further emphasizes its potential for specific industrial applications. Nonetheless, one must judiciously weigh these benefits against the project’s unique requirements.

Conclusion

In conclusion, Arduino emerges as a valuable tool for prototyping and early-stage development in various industrial settings. While not a universal solution, its nuanced application can bridge the gap between innovation and practicality. By understanding its strengths and limitations, businesses can leverage Arduino effectively in specific industrial automation and control projects.

You may also like:

What are the applications of Arduino in robotics and home automation?

What are the limitations of Arduino in terms of processing power and memory?