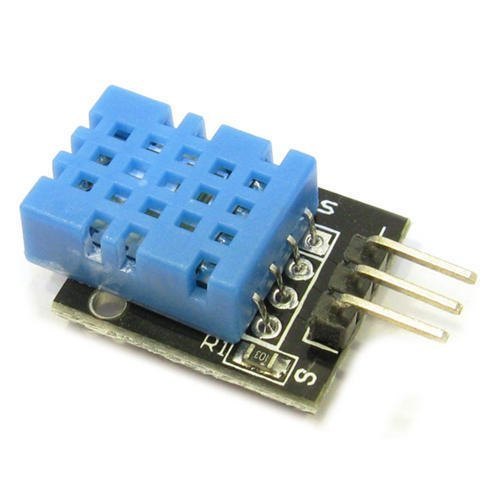

Humidity sensors, those unsung heroes of modern technology, quietly go about their business, measuring the invisible dance of water vapor in the air. These electronic marvels play a pivotal role in various applications, tirelessly monitoring and gauging humidity levels. Let’s embark on a journey to understand the intricate world of humidity sensors, where science meets practicality.

Types of Humidity Sensors

1. Capacitive Humidity Sensors

Capacitive humidity sensors, akin to humidity detectives, specialize in sensing relative humidity (RH). They operate by measuring electrical capacitance, offering precise readings that illuminate the humidity landscape. Noteworthy advantages include minimal power consumption and robust output signals.

2. Resistive Humidity Sensors

Resistive humidity sensors join the humidity quest, designed specifically for sensing RH. These sensors employ electrical resistance as their tool of choice, compact in size and tailored for remote operations. However, they bear a sensitivity to chemical vapors and other pollutants.

3. Thermal Conductivity Humidity Sensors

Stepping into the realm of absolute humidity (AH), thermal conductivity humidity sensors shine. They measure the thermal conductivity of the surrounding air, proving their mettle in high-temperature environments and corrosive situations.

The Symphony of Working Principles

At the core of these sensors lies a simple yet ingenious working principle. They keenly observe alterations in electrical currents or temperature in the surrounding air. Picture a sensor probe, housing an element that detects humidity and a thermistor that gauges temperature. Capacitive and resistive humidity sensors rely on electrical capacitance and resistance, respectively, while thermal conductivity sensors measure the thermal conductivity of the air.

Pros and Cons: Navigating the Humidity Landscape

Advantages

Humidity sensors boast an impressive array of advantages. From accurate moisture measurement to thwarting the onset of mold and mildew, they contribute to optimal comfort, energy efficiency, and precise process control. Additionally, these sensors play a pivotal role in weather forecasting and safeguarding electronic components from the perils of moisture damage.

Challenges

Yet, like any technological marvel, humidity sensors have their set of challenges. Calibration and drift pose potential pitfalls, sensitivity to contaminants raises concerns, and a limited lifespan necessitates thoughtful consideration. Variability across environments, response time concerns, and susceptibility to electromagnetic interference add further layers of complexity.

Applications: Where Humidity Sensors Reign Supreme

Humidity sensors are the unsung heroes in a myriad of applications :

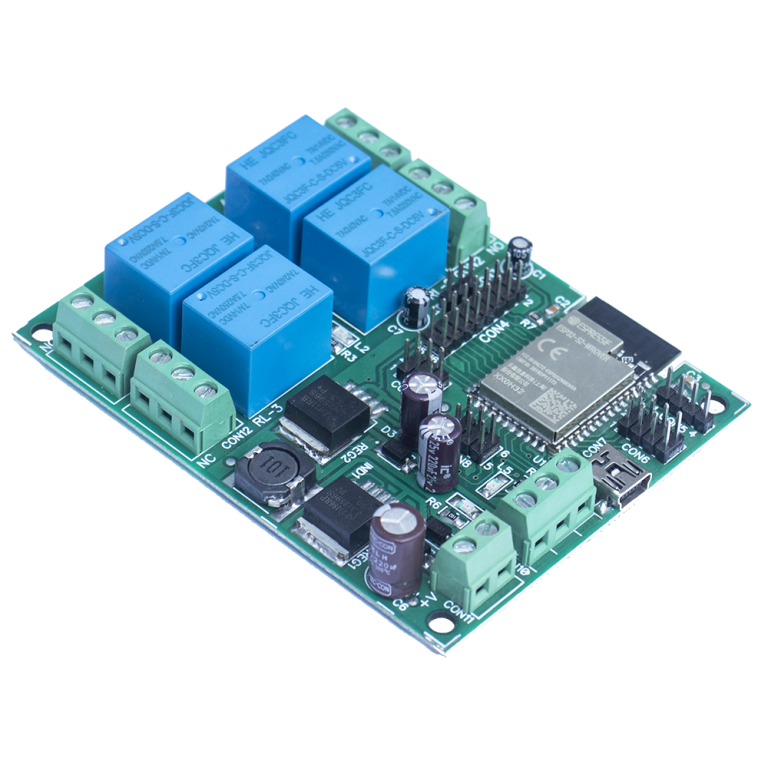

- HVAC Systems: Humidity sensors play a crucial role in maintaining energy-efficient climate conditions.

- Medical Applications: From incubators to neonatal intensive care facilities, these sensors ensure precise humidity levels critical for patient well-being.

- Weather Stations: Ground and airborne weather stations utilize humidity sensors to track environmental conditions, aiding in accurate weather forecasting.

- Automotive Industry: In the automotive realm, humidity sensors contribute to controlling the temperature within the car’s cabin.

- Diverse Industries: From printers, ovens, and greenhouses to food processing and laboratory applications, the reach of humidity sensors spans far and wide.

The Evolving Landscape of Humidity Sensors: A Glimpse into the Future

As technology marches forward, the realm of humidity sensors is not left behind. Innovations continue to reshape the landscape, promising enhanced capabilities and addressing existing challenges.

Advancements in Calibration Precision

One of the persistent challenges faced by humidity sensors is the need for precise calibration. However, ongoing research and development are focused on refining calibration processes, ensuring that these sensors deliver consistently accurate readings over extended periods. The future holds the promise of calibration methods that mitigate drift and enhance overall reliability.

Tackling Sensitivity to Contaminants

The sensitivity of humidity sensors to contaminants has been a concern, particularly in industrial settings. Future iterations are expected to incorporate advanced filtering mechanisms, reducing susceptibility to pollutants. This enhancement is crucial in maintaining the longevity and accuracy of humidity sensors in diverse environments.

Extended Lifespan through Material Innovation

The limited lifespan of humidity sensors has been a drawback in certain applications. Researchers are exploring novel materials and manufacturing techniques that can extend the operational life of these sensors. This not only contributes to sustainability but also reduces the frequency of replacements, making humidity sensors more cost-effective in the long run.

Enhanced Response Time for Real-time Monitoring

In applications where real-time monitoring is paramount, such as critical manufacturing processes, researchers are striving to reduce the response time of humidity sensors. Faster response times ensure that changes in humidity levels are detected and acted upon promptly, preventing potential issues before they escalate.

Adapting to Varied Environments

The variability of humidity levels across different environments has been a challenge for standard sensors. Future developments aim to create sensors with adaptive capabilities, capable of seamlessly adjusting to diverse surroundings. This adaptability ensures accurate readings and reliable performance across a spectrum of conditions.

Innovations in Electromagnetic Interference Resilience

Electromagnetic interference has been a concern, particularly in settings with multiple electronic devices. Future humidity sensors are anticipated to feature improved shielding and interference-resistant designs, ensuring robust performance even in crowded electromagnetic environments.

The Future Applications of Humidity Sensors

Looking ahead, the applications of humidity sensors are poised to expand further. From smart homes that adjust climate conditions based on real-time humidity data to precision agriculture where these sensors optimize growing conditions in greenhouses, the potential is vast. Industries like pharmaceuticals and semiconductor manufacturing, where environmental control is critical, stand to benefit from the continuous evolution of humidity sensing technology.

Final Thoughts: Navigating the Humidity Frontier

In conclusion, the journey of humidity sensors is an ongoing exploration of innovation and refinement. As we look forward, the horizon is bright with possibilities. These unassuming devices, with their capacity to measure the intangible, continue to play an integral role in shaping our environments and advancing technological frontiers. The tale of humidity sensors is far from over; it’s a story of adaptation, enhancement, and a commitment to precision in an ever-changing world.

+ There are no comments

Add yours